What is Salt Processing

Salt processing is a crucial industry that involves several intricate steps to transform raw salt into the refined product we use daily. In this comprehensive guide, we’ll walk you through the essential processes of salt processing and explore the cutting-edge machinery offered by Buraq Engineering, a prominent player in Pakistan’s salt industry.

Introduction to Salt Processing:

Salt, a staple ingredient in our diets, undergoes a fascinating journey from its natural state to the refined crystals we find in our kitchens. Understanding the intricacies of salt processing is essential to appreciate the effort behind the product’s journey from extraction to packaging.

Salt Processing Steps

- Harvesting Salt

- Purification Process

- Size Reduction and Refinement

- Drying the Salt

- Iodization Process

- Quality Control Measures

- Packaging the Salt

Harvesting Salt:

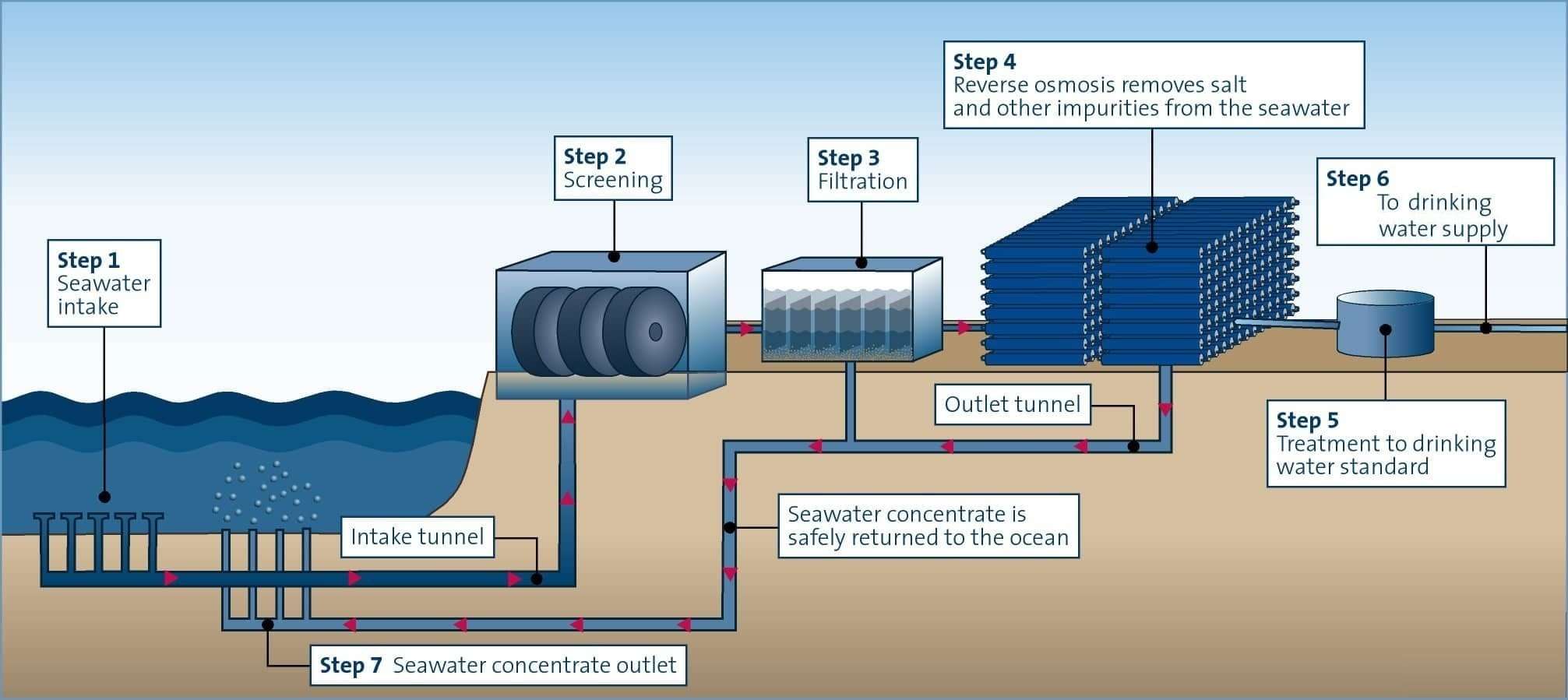

The first step in salt processing involves harvesting salt from its natural sources. This can be done through solar evaporation, where seawater is collected in vast ponds and left to evaporate under the sun, or through mining, where salt deposits are extracted from underground mines using specialized machinery.

Purification Process:

Once harvested, raw salt often contains impurities that need to be removed. This purification process typically involves washing the salt with water to dissolve and remove impurities like dirt and debris. Salt processing plants utilize salt washing machines for this purpose.

Size Reduction and Refinement:

After purification, the salt crystals undergo size reduction and refinement processes. This includes crushing and grinding the salt crystals to achieve a uniform size and texture. Advanced machinery, such as crushers and grinders, are employed for this task.

Drying the Salt:

Excess moisture in the salt crystals needs to be removed to prevent clumping and ensure the salt remains free-flowing. Industrial dryers or drying chambers are used to evaporate the moisture, leaving behind dry salt crystals ready for further processing.

Iodization Process:

In many regions, salt is iodized to prevent iodine deficiency disorders. The iodization process involves adding precise amounts of iodine to the salt using specialized equipment. This ensures that the salt is enriched with iodine, providing essential nutrients to consumers.

Quality Control Measures:

Throughout the processing journey, stringent quality control measures are implemented to ensure that only the highest quality salt reaches the market. This includes screening and grading the salt crystals to assess purity, size, and color.

Packaging the Salt:

The final step in salt processing is packaging the refined salt for distribution and sale. Salt packaging machines are used to fill and seal bags or containers with the processed salt. These machines ensure efficient packaging while maintaining the quality and integrity of the product.

Buraq Engineering stands out as a leading manufacturer of salt processing machinery in Pakistan. Their advanced machines, designed for salt washing, crushing, drying, and packaging, play a crucial role in the efficiency and quality of salt processing plants across the country.

Final Thoughts

In conclusion, salt processing is a complex yet essential industry that relies on advanced machinery and meticulous processes to deliver high-quality salt products to consumers. By understanding the key steps involved in salt processing and the role of advanced machinery, we can appreciate the effort and technology behind this everyday commodity.

This guide provides valuable insights into the salt processing journey and highlights the importance of machinery, particularly those provided by Buraq Engineering, in ensuring the efficiency and quality of salt processing operations in Pakistan.